Hotmelt adhesives are used for the narrow-surface sealing of panel-shaped wood workpieces. The processing quality is strongly dependent on the temperature at which the adhesive is applied. The adhesive applied to the strip is melted by transporting the strip past a controllable heat source. When processing on CNC machines, the changing processing speed of the machine must also be taken into account.

In this project, the ISD is conducting research together with HOMAG GmbH on predictive algorithms for controlling the adhesive temperature. The core topics of the research work are:

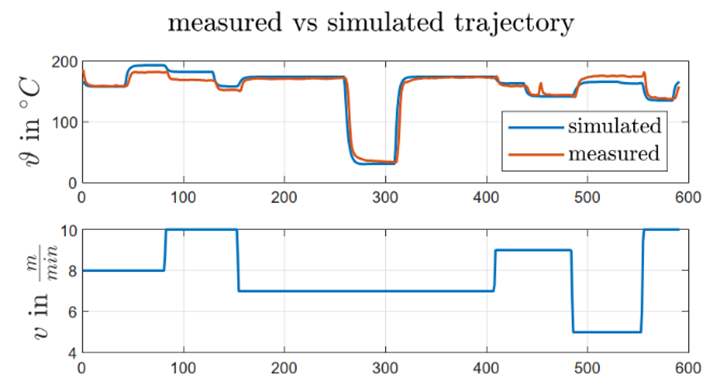

- Mathematical modeling of the process

- Model predictive control

- Communication with the machine control (CNC)

On the part of the ISD, the project is supervised by Ruven Weiss.

Ruven

Weiss

Room

E

203

rweiss@htwg-konstanz.de

Office hours

Nach Vereinbarung

Prof. Dr.

Johannes

Reuter

Prodekan, Studiendekan Elektrische Systeme M. Eng. (EIM) <br> Fachgebiet: Regelungstechnik

Room

F

313

+49 7531 206-266

jreuter@htwg-konstanz.de

Publikationen im Kontext dieses Projektes

- Ruven Weiss, Moritz Diehl, Harald Rieger, Johannes Reuter. Modeling and temperature control of a moving substrate. IFAC-PapersOnLine 54.6, 2021, pp. 212-217. [Link]

Back to research