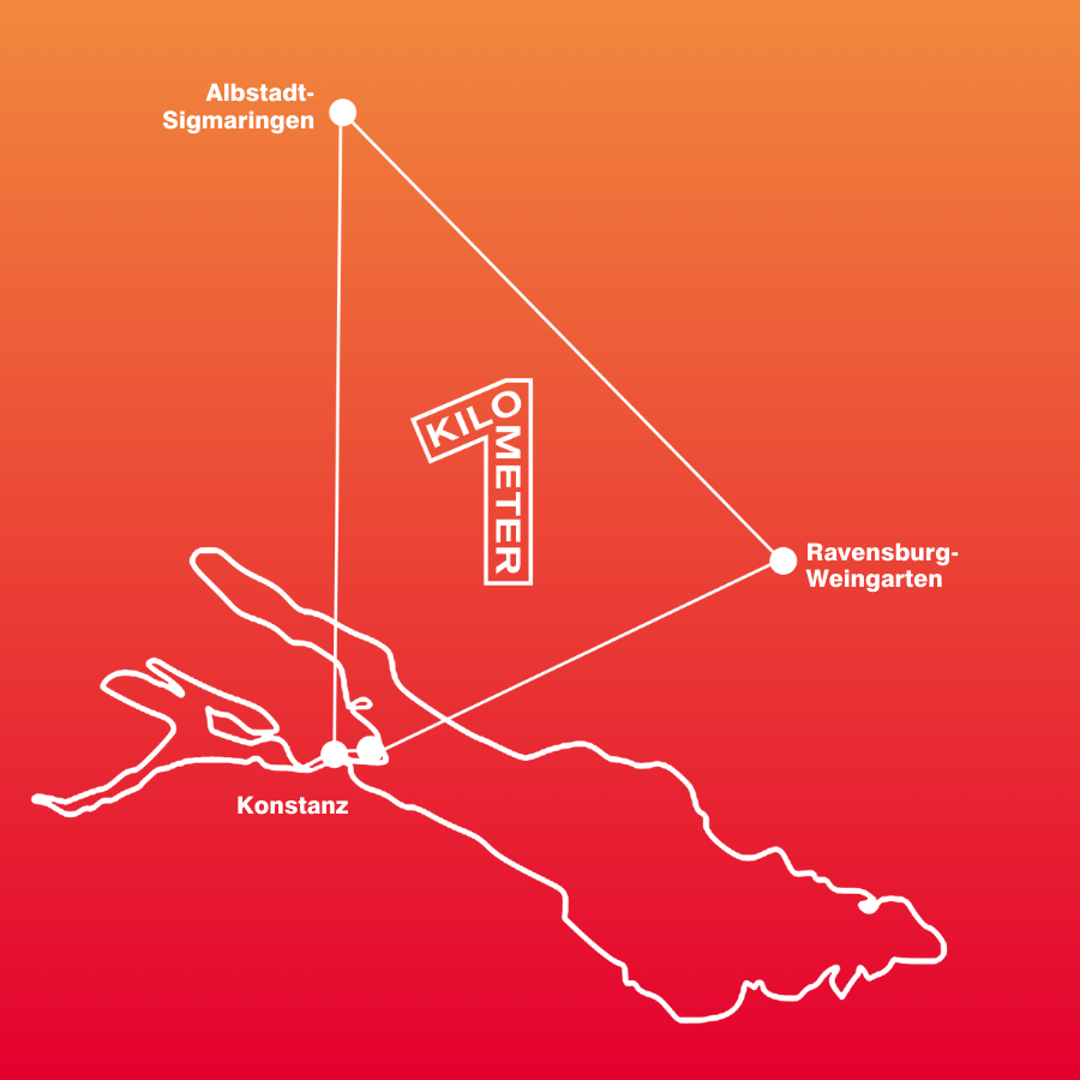

UNISPHERE is a start-up founded in 2017 by Christoph Schlettig and Michael Anger, based in Gilching, Germany, which is involved in the development, distribution, and flight operation of solar-powered drones and all related activities. These include consulting and engineering services in the field of aerospace technology, as well as training and further education of personnel for the operation of solar-powered drones. The preferred areas of application for solar-powered drones are monitoring the environment, border areas, and natural disasters, as well as providing broadband internet and communication in emergency operations.

Designed as a flight management platform, UNISPHERE combines solar-powered drones, flight management services, and expertise in unlimited flights. To this end, the start-up draws on the knowledge of SOLARIMPULS, where the two founders contributed as flight directors to the successful first circumnavigation of the globe by a purely solar-powered aircraft. During their six years at SOLARIMPULS, Christoph Schlettig and Michael Anger were able to build up sufficient expertise in aerospace engineering, feasibility analyses, and simulations. This enables UNISPHERE to offer its customers safe and efficient flight operations as well as integration into air traffic management.

The flight management platform offers customers the following services:

- A centralized control point for the global coordination of versatile HAPS (High Altitude Platform Station)

- Cooperation with aviation authorities, national agencies, and air traffic control

- Customized flight profiles and IT solutions for data interfaces

- Launch, restoration, and maintenance of HAPS

UNISPHERE is funded by the BMWI's INVEST financing program and is part of the ESA Business Incubation Centre Bavaria. The IST Institute supports the UNISPHERE team in the area of strategy through Dr.-Ing. Guido H. Baltes and in business development through Christoph Selig.